From November 9 to 15, Peeters Group will be present at Agritechnica in Hanover! Visit us in Hall 05, Booth 05D03 and...

Stay up-to-date with the latest developments at Peeters Group and read the most important news, inspiring content & practical information.

From November 9 to 15, Peeters Group will be present at Agritechnica in Hanover! Visit us in Hall 05, Booth 05D03 and...

Pitbull will be present at this year's bauma trade fair, taking place from April 7 to 13, 2025, in Munich....

Peecon Rapide XL-V : an ideal alternative to self-propelled vertical feed mixer wagons This loading device is a very reliable...

Pitbull has achieved ISO certification in 2024!

What a succes! It may have taken a while, but the fairs are back. Our dealers Asjes Alkmaar and D....

Peecon truckmount 34m3 – Idaho (USA) Shrinking is generally not your friend. Whether you’re talking about your favorite pair of...

Peecon is best known for its tippers, slurry tanks and feed mixers. Three years ago, the Dutch manufacturer also started...

Another successful trade fair! Our Austrian importer aZb Agrartec GmbH took part in the Rieder Messe fair. It took place...

Find the bunny and win a softshell Pitbull/Peecon jacket! Peeters Group wishes everyone a happy Easter! To make the Easter...

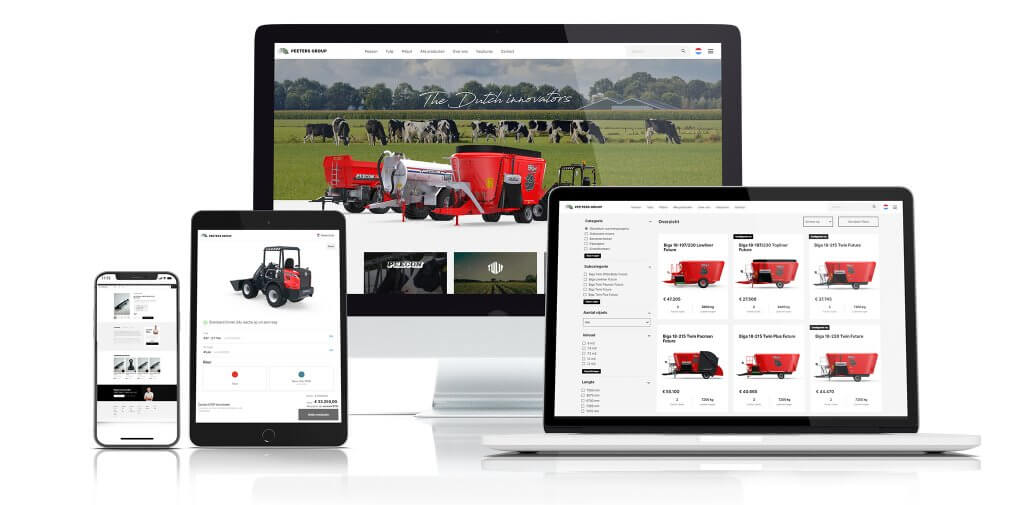

Peeters Group released its new website online on 15-10-2020. From now on, our customers will be able to choose more...